Automotive Coatings

Contact Us

Toll Free 1.800.747.1084

Local 309.523.2121

Automotive OEM Coatings That Protect Your Reputation

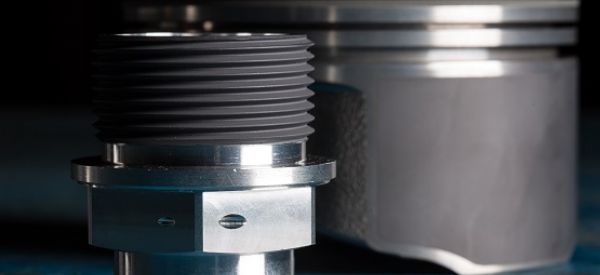

In 1972, Sandstrom partnered with a major domestic automobile supplier to formulate and produce gasket coatings. Later Sandstrom partnered with an automotive manufacturer to design a friction-reducing material for use on gas engine pistons. Then in 1984, a second domestic supplier chose Sandstrom to formulate and provide a product to inhibit corrosion on a major starter assembly part. Why so much history? Sandstrom continues to update formulations on many of those original products. And you can count on us to get you just about every type of gasket or other automotive parts coating you can imagine—everything from piston skirts to sound deadeners to wire coating. Let us know what you need. We’ll take care of the rest.

DISCLAIMER

Automotive gasket coating and piston skirt coating products are sold by manufacturer’s batch size only.

Click a product below to learn more

Product Help Form

Safety & Technical Data Sheets

Specifications Search

Request a Quote

For Automotive Coatings

“Sandstrom’s 099 coating sprays so much better than other coatings that conforms to the MIL-PRF-46010 specification and is easy to work with being a waterborne coating”

“We have worked with Sandstrom Products for a little more than ten years. While their products are extraordinary, it is their customer service that makes them a premier… read more

“In 2012 we were looking to add heat cured Solid Film Lubricants to our capabilities as a Dry Film Lubricants applicator. I contacted Sandstrom Products for a quote on material… read more